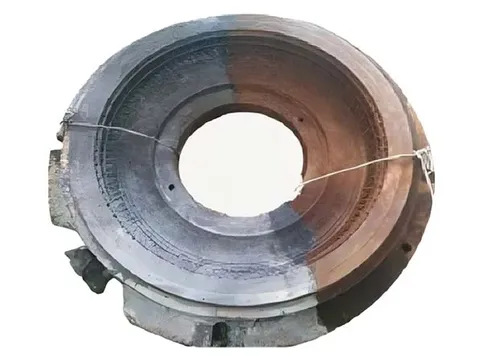

The laser cleaning machine stands as an innovative solution to replace traditional chemical cleaning and sandblasting processes, thanks to its non-contact, pollution-free, and high-precision technical characteristics. Its core advantages include: zero chemical solvents, making it environmentally friendly; a laser cleaning speed that is 3-5 times faster than traditional sandblasting; and a laser lifespan of up to 100,000 hours. The non-contact cleaning avoids mechanical damage and chemical corrosion to the substrate material, maximizing the preservation of the material's original properties and surface integrity.

With ongoing technological innovation, laser cleaning applications are becoming increasingly widespread in fields such as aerospace, automotive manufacturing, tire molds, cultural heritage preservation, and logistics and transportation. Simultaneously, its integrated development with other technologies will enable it to play a key role in more specialized scenarios, positioning it as the mainstream surface cleaning technology of the future.

-

- Pulse Laser Cleaning Machine Ultra-light handheld design: Weighs only 0.78kg with ergonomic grip for one-handed use. Effortlessly reaches deep cavities and hard-to-reach areas.

Non-contact, zero-consumable cleaning: Requires no chemicals or abrasives. Leaves base material virtually untouched with less than 0.0003mm surface damage. Learn more -

- Laser wavelength: 1064nm

- Cooling method: air cooling

- Scanning width: 175×175mm

- Machine weight: 40kg

Contact Us

-

- CW Laser Cleaning Machine Non-contact, zero-consumable cleaning: Cleans rust, paint, and grease without chemicals or abrasives. Zero secondary pollution and no damage to the base material.

Ergonomic handheld gun: Weighing only 600g, the laser head features a lightweight, ergonomic design for one-handed operation—perfect for deep grooves and hard-to-reach areas. Learn more -

- Laser wavelength: 1080nm

- Cooling method: water cooling

- Scanning width: 10-100mm

- Machine weight: 110kg

Contact Us