Laser welding is a highly efficient processing technology that utilizes a high-energy-density laser beam as a heat source to achieve precise joining by melting materials. It is suitable for metals such as stainless steel, aluminum alloy, titanium alloy, and copper, as well as non-metals like plastics and composite materials. It particularly excels in joining dissimilar materials, such as copper-aluminum and steel-plastic. Application areas cover industries including automotive manufacturing, electronics, aerospace, medical devices, sports equipment, furniture manufacturing, jewelry, and mold manufacturing.

For different industries and applications, we provide tailored laser welding solutions, offering various types of laser welding equipment, such as handheld laser welding machines, galvo laser welding machines, jewelry laser spot welders, and mold laser welding machines.

-

- Automatic Fiber Laser Welding Machine The automatic fiber laser welding machine (platform type) is designed specifically for large-scale manufacturing scenarios, with core advantages of full automation, high stability, and millimeter-level precision. It employs a high-power fiber laser, featuring a spot diameter of ≤0.1mm and precisely controllable heat input (fluctuation <2%). Learn more

-

- Laser wavelength: 1064nm

- Welding speed: 0-20m/min (intelligent adjustable)

- Cooling method: water cooling

- Machine weight: 360kg

Contact Us

-

- Handheld Laser Welding Machine The handheld laser welding machine redefines traditional welding processes with its core advantages of high precision, lightweight design, and multi-scenario adaptability. This equipment utilizes fiber laser technology, with power covering 1500W-6000W, a spot diameter of ≤0.2mm, and a heat-affected zone (HAZ) of <0.5mm. Learn more

-

- Laser wavelength: 1080nm

- Welding speed: 0-20m/min (intelligent adjustable)

- Cooling method: water cooling

- Machine weight: 150kg

Contact Us

-

- Air-Cooled Laser Welding Machine The air-cooled handheld laser welding machine offers core advantages: efficient heat dissipation, portable flexibility, and multi-scenario adaptability. This equipment utilizes fiber laser technology, with power covering 700W-2000W, a spot diameter of ≤0.2mm, and a heat-affected zone (HAZ) of <0.5mm. Learn more

-

- Laser wavelength: 1080nm

- Welding speed: 0-20m/min (intelligent adjustable)

- Cooling method: air cooling

- Machine weight: 54kg

Contact Us

-

- Galvo Laser Welding Machine The galvo scanner achieves a dynamic response speed of up to 7000mm/s. Coupled with a 1064-1080nm high-energy-density fiber laser, welding efficiency is boosted by over 8 times compared to traditional equipment, with a single-day production capacity exceeding 3000 pieces. Learn more

-

- Laser wavelength: 1064nm

- Max. pulse energy: 30J (QCW mode)

- Scanning speed: ≤7000mm/s

- Repeatability accuracy: ±0.02mm

Contact Us

-

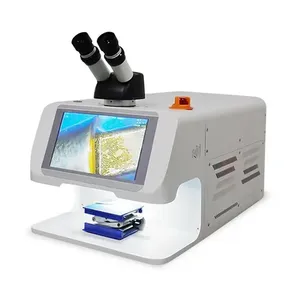

- Jewelry Laser Spot Welding Machine The jewelry laser spot welding machine utilizes 1064nm wavelength YAG laser technology, offering a single pulse energy of up to 90J and an adjustable spot size from 0.1-3.0mm. Learn more

-

- Laser type: YAG laser

- Pulse width: 0.1-5ms

- Laser spot size: 0.1-3mm

- Machine weight: 35kg

Contact Us

-

- Mould Repair Laser Welding Machine The mould repair laser welding machine features a focused spot diameter of merely 0.2-3.0mm, allowing for micron-level repairs with just a gentle touch on the mold surface. Learn more

-

- Laser wavelength: 1064nm

- Pulse width: 0.1-10ms

- Cooling method: water cooling

- Machine weight: 260kg

Contact Us