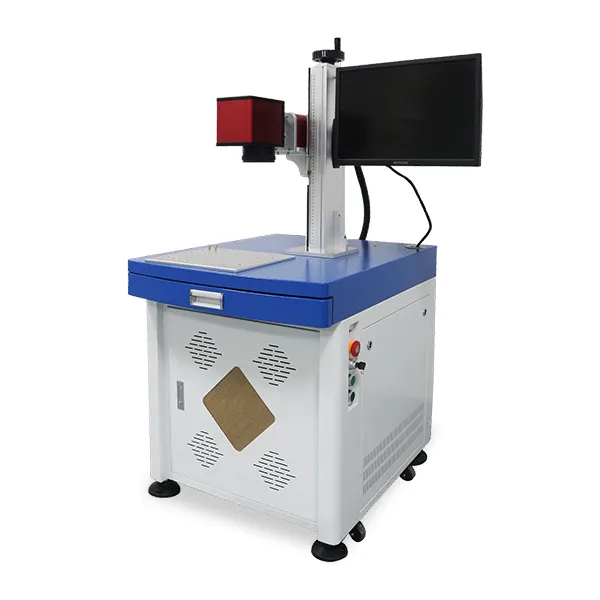

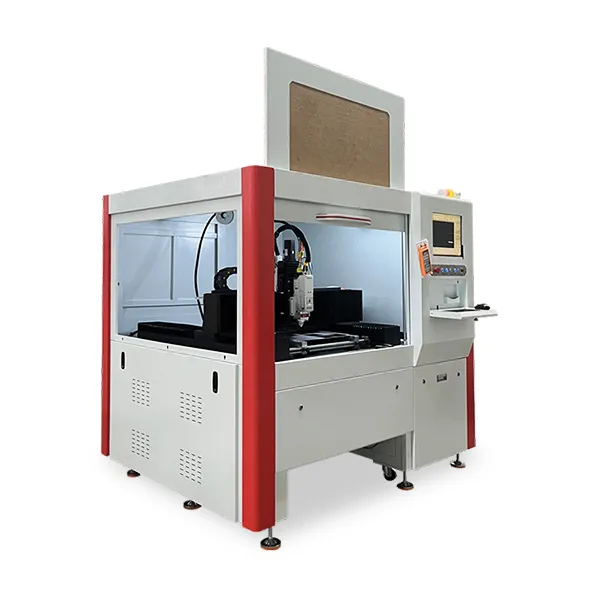

Jewelry Laser Spot Welding Machine

Jewelry Laser Spot Welding Machine

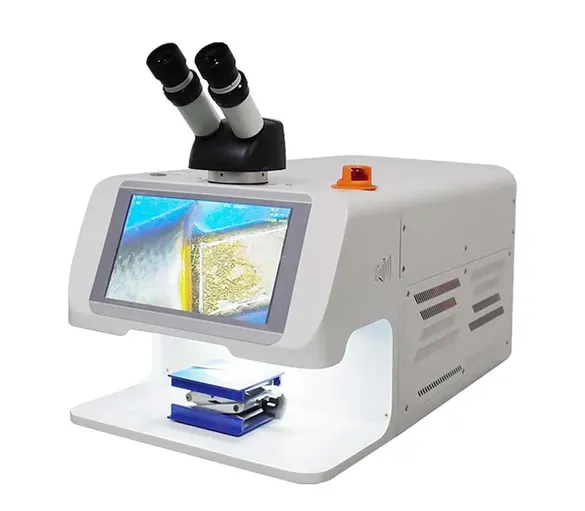

- Laser type YAG laser

- Pulse width 0.1-5ms

- Laser spot size 0.1-3mm

- Machine weight 35kg

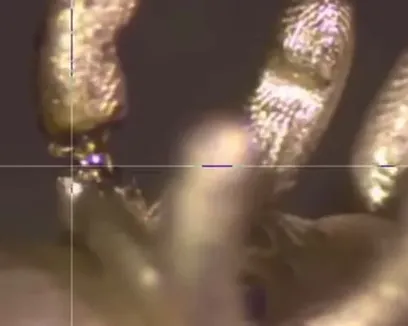

The jewelry laser spot welding machine utilizes 1064nm wavelength YAG laser technology, offering a single pulse energy of up to 90J and an adjustable spot size from 0.1-3.0mm. It supports non-destructive welding of highly reflective metals such as gold, silver, and platinum, with a heat-affected zone (HAZ) of less than 0.2mm, ensuring no oxidation or deformation on the jewelry surface. Integrating a high-definition CCD microscope observation system and an electronic light filter device, operators can clearly view welding details without wearing protective goggles. Coupled with an ergonomic design, it can complete over 500 precise welding tasks per day, boosting efficiency by 5 times compared to traditional methods. It is an innovative tool for jewelry repair, setting, and micro-engraving.

Standard Configuration

Standard Configuration Optional Configuration

Optional Configuration Accessory List

Accessory List