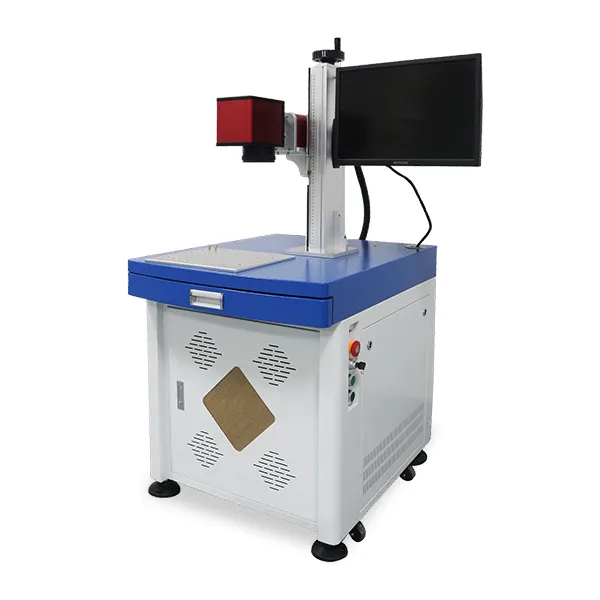

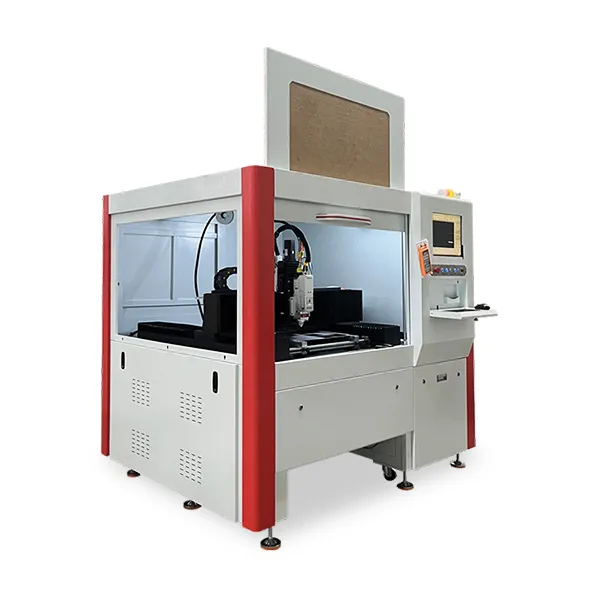

Automatic Fiber Laser Welding Machine

Automatic Fiber Laser Welding Machine

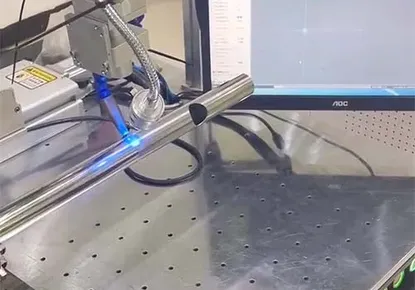

- Laser wavelength 1064nm

- Welding speed 0-20m/min (intelligent adjustable)

- Cooling method water cooling

- Machine weight 360kg

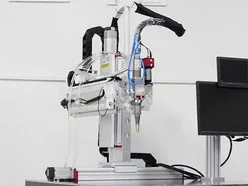

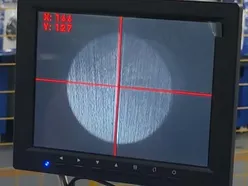

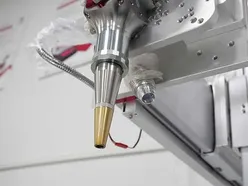

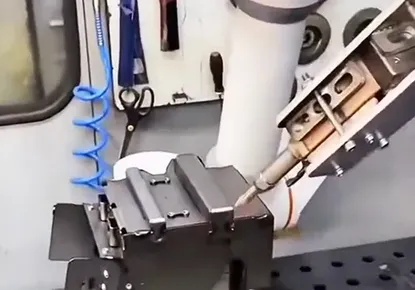

The automatic fiber laser welding machine (platform type) is designed specifically for large-scale manufacturing scenarios, with core advantages of full automation, high stability, and millimeter-level precision. It employs a high-power fiber laser, featuring a spot diameter of ≤0.1mm and precisely controllable heat input (fluctuation <2%). This enables high-speed seamless welding of materials such as stainless steel, aluminum alloys, and titanium alloys, achieving weld strengths of over 95% of the base material with smooth, oxidation-free surfaces. The equipment integrates an intelligent motion platform and a CCD vision positioning system, supporting offline programming and real-time correction, with a repetitive positioning accuracy of ±0.02mm. It is suitable for precision welding demands in applications like automotive components, battery trays, and 3C electronics. Its modular structure (total footprint <5m²) allows for seamless integration into smart production lines, with a single machine daily capacity exceeding 3000 pieces and a yield rate of ≥99.5%, making it the preferred tool for quality and efficiency enhancement in high-end manufacturing.

Standard Configuration

Standard Configuration Optional Configuration

Optional Configuration Supporting Equipment

Supporting Equipment Consumables / Wearable Parts List

Consumables / Wearable Parts List