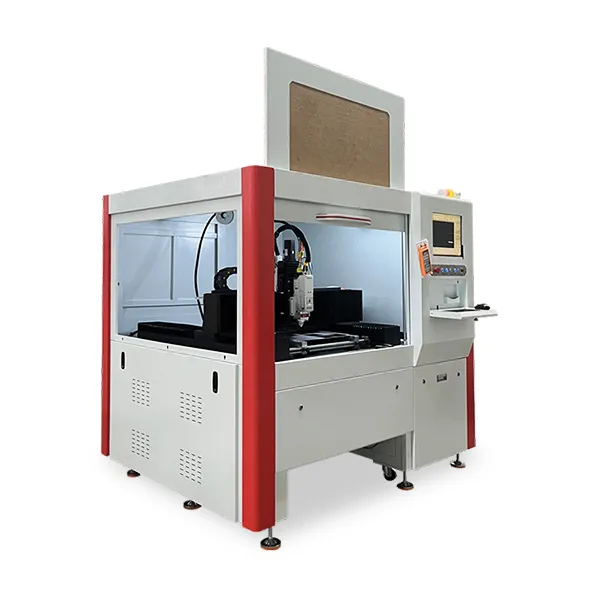

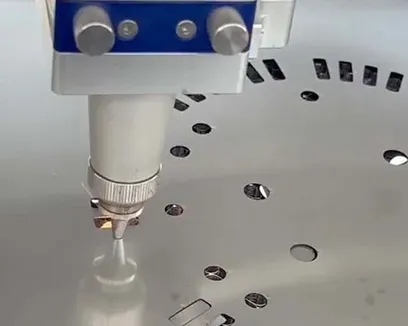

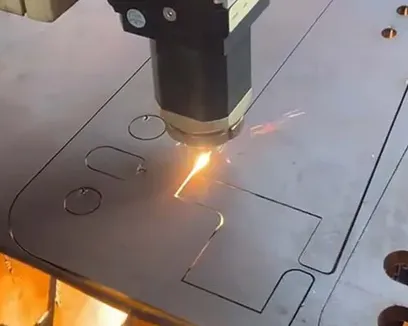

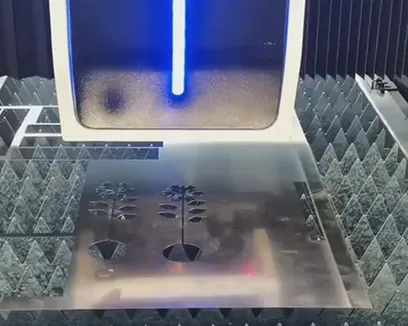

Fiber Laser Precision Cutting Machine

Fiber Laser Precision Cutting Machine

- Laser power 1500W

- Repeatability accuracy ±0.05mm

- Power supply 380V/50Hz

- Machine weight 1850kg

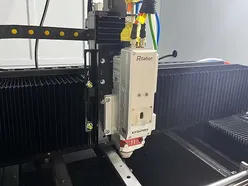

The fiber laser precision cutting machine features an aerospace-grade aluminum alloy frame and a high-precision integrated structure. It houses a modular fiber laser and a multi-axis linkage servo system. Core components, such as the Raytools cutting head, Yaskawa servo motors, and Hiwin linear guides, are all from international top brands, ensuring the equipment maintains a repeat positioning accuracy of ±0.02mm even during high-speed operation. The overall machine layout is compact, with hidden designs for both cooling air ducts and cable management, enhancing both safety and operational convenience.

Standard Configuration

Standard Configuration Supporting Equipment

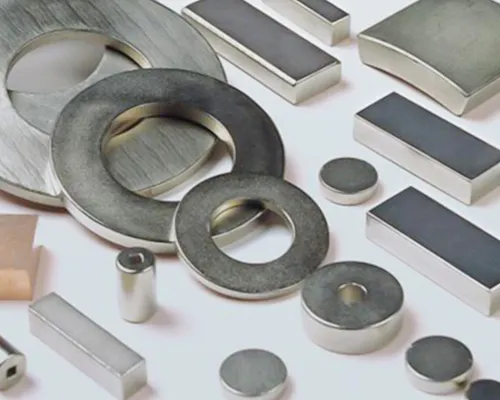

Supporting Equipment Consumables / Wearable Parts List

Consumables / Wearable Parts List