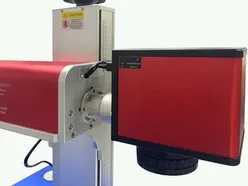

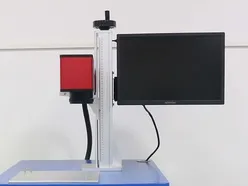

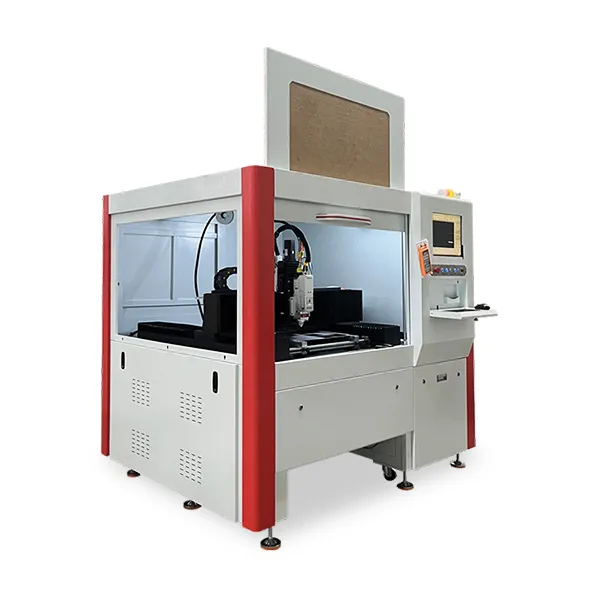

Galvo Laser Welding Machine

Galvo Laser Welding Machine

- Laser wavelength 1064nm

- Max. pulse energy 30J (QCW mode)

- Scanning speed ≤7000mm/s

- Repeatability accuracy ±0.02mm

The galvo laser welding machine offers outstanding features:

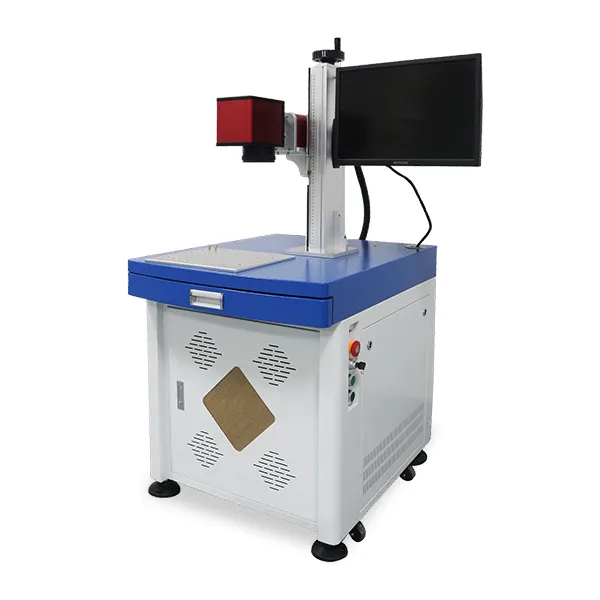

- Ultra-high speed scanning: The galvo scanner achieves a dynamic response speed of up to 7000mm/s. Coupled with a 1064-1080nm high-energy-density fiber laser, welding efficiency is boosted by over 8 times compared to traditional equipment, with a single-day production capacity exceeding 3000 pieces.

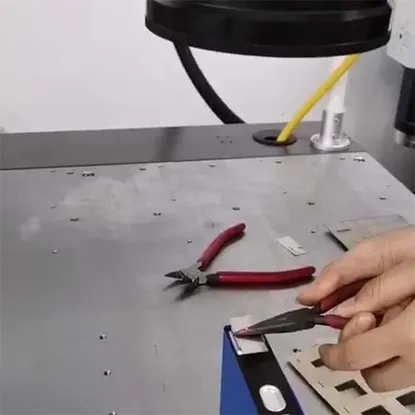

- Precision processing capability: The spot diameter is adjustable from 0.1-2.0mm, with a repetitive positioning accuracy of ±0.02mm. It supports seamless welding of dissimilar metals (copper-aluminum, titanium-molybdenum) and ultra-thin materials down to 0.1mm, achieving weld strengths of over 95% of the base material.

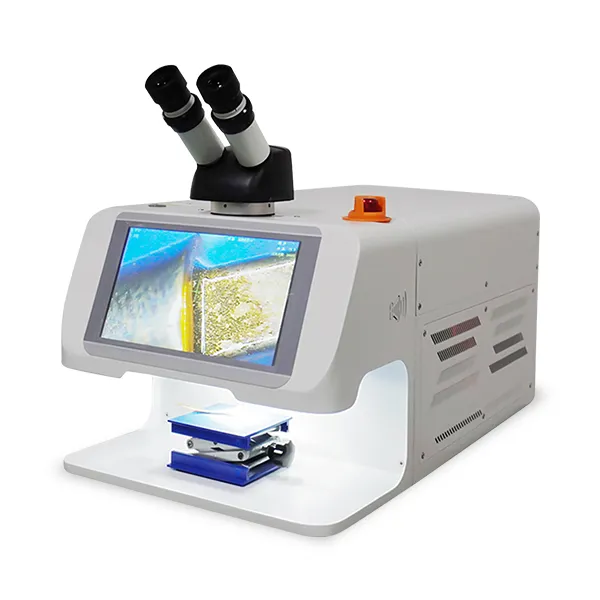

- Intelligent integration: Standardly equipped with a CCD vision positioning system and dynamic focusing system, it is perfectly suited for automated production lines, ensuring a yield rate of ≥99.5%.

Standard Configuration

Standard Configuration Optional Configuration

Optional Configuration Accessory List

Accessory List