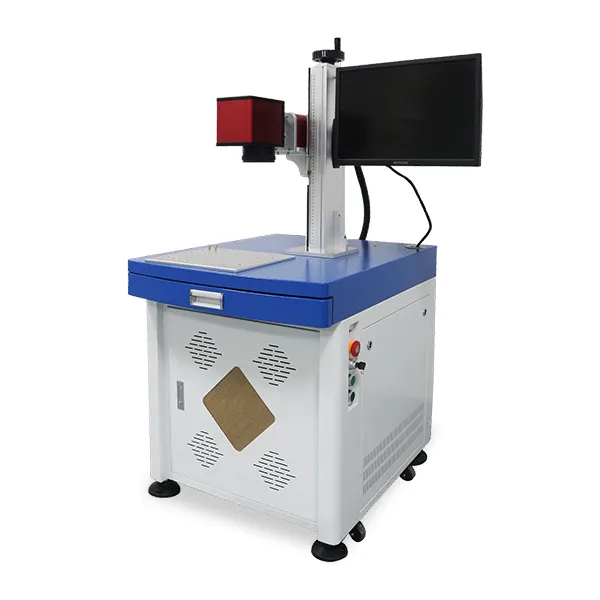

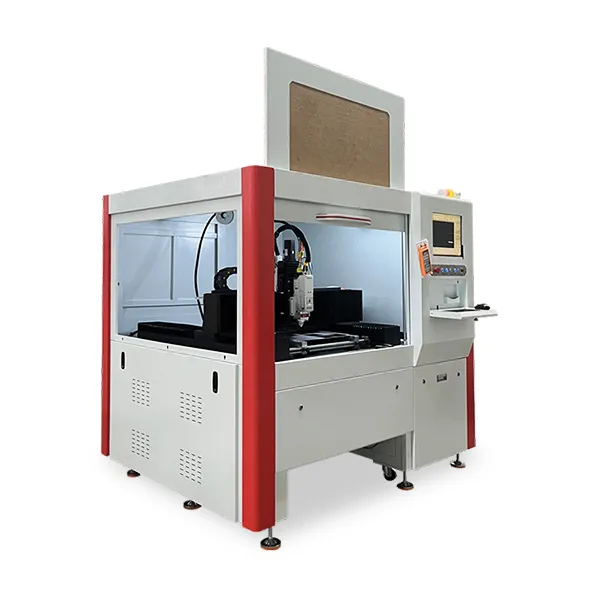

Air-Cooled Laser Welding Machine

Air-Cooled Laser Welding Machine

- Laser wavelength 1080nm

- Welding speed 0-20m/min (intelligent adjustable)

- Cooling method air cooling

- Machine weight 54kg

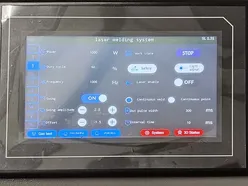

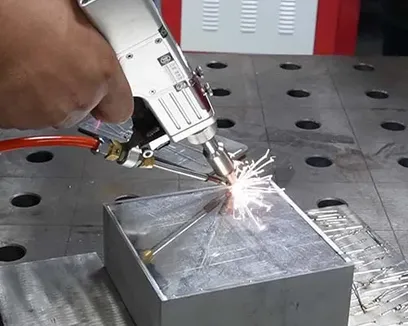

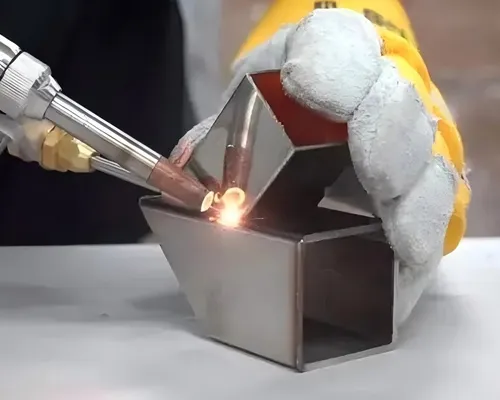

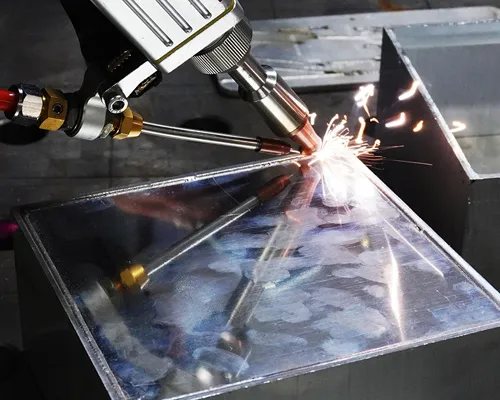

The air-cooled handheld laser welding machine offers core advantages: efficient heat dissipation, portable flexibility, and multi-scenario adaptability. This equipment utilizes fiber laser technology, with power covering 700W-2000W, a spot diameter of ≤0.2mm, and a heat-affected zone (HAZ) of <0.5mm. The weld strength is comparable to the base material, and the surface is smooth with no oxidation. Its integrated air-cooled design reduces the equipment weight to 54kg and volume to <0.3m³, supporting single-person transport and vehicle-mounted operations, making it suitable for complex scenarios like workshops, construction sites, and outdoors. Combined with intelligent preset parameters and a human-machine interactive touch screen, novice operators can get started with just 1 hour of training. It achieves a welding speed of 2-10cm/s, boosting efficiency by over 3 times compared to traditional arc welding. It is particularly ideal for demanding fields such as automotive repair, metal processing, and construction installation, serving as a benchmark choice for industrial-grade portable welders.

Standard Configuration

Standard Configuration Optional Configuration

Optional Configuration Consumables / Wearable Parts List

Consumables / Wearable Parts List