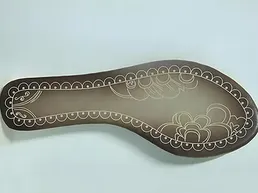

Spanish Shoe Sole Manufacturer Orders CO2 Laser Marking Machine

Spanish Shoe Sole Manufacturer Orders CO2 Laser Marking Machine Russian Animal Ear Tag Producer Orders Six-Station Laser Marking Machines

Russian Animal Ear Tag Producer Orders Six-Station Laser Marking Machines Italian Manufacturer Orders Laser Cleaning Machine

Italian Manufacturer Orders Laser Cleaning Machine Saudi Arabian Textile Artisan Orders 300W CO₂ Laser Marking Machine

Saudi Arabian Textile Artisan Orders 300W CO₂ Laser Marking Machine Czech Auto Repair Center Owner Orders 1500W Laser Cleaning Machine

Czech Auto Repair Center Owner Orders 1500W Laser Cleaning Machine U.S. Plastic Pipe Manufacturer Orders Laser Marking Machine

U.S. Plastic Pipe Manufacturer Orders Laser Marking Machine The UAE Jewelry Designer Purchases 50W Fiber Laser Marking Machine

The UAE Jewelry Designer Purchases 50W Fiber Laser Marking Machine Samsung Project Manager Purchases 10W UV Laser Marking Machine

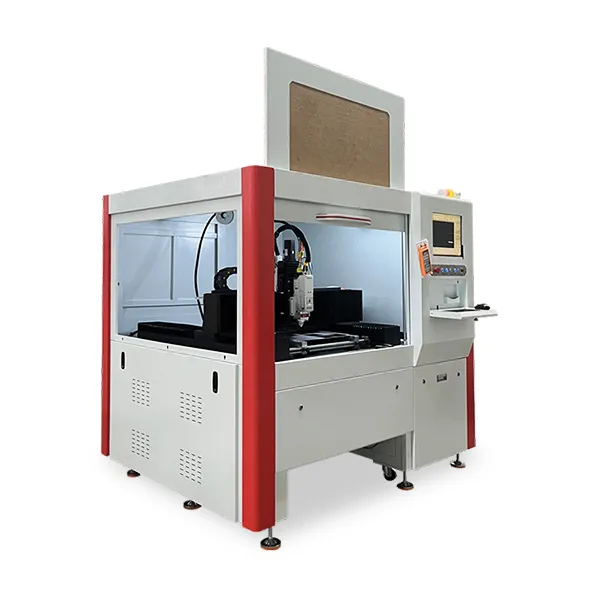

Samsung Project Manager Purchases 10W UV Laser Marking Machine

Client Background

Mr. Jung is a project manager at Samsung, tasked with finding a high-precision laser solution for a specific project.

Application Requirements

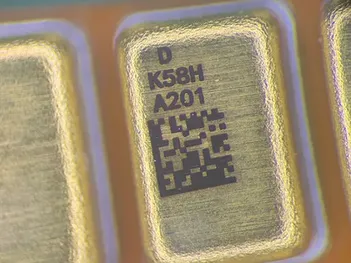

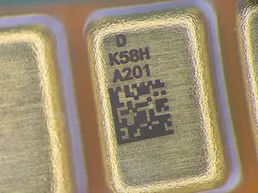

The need was to laser mark black miniature data matrix codes on metal components of a special PCB product. The PCB's total size was 202x46mm, with metal components distributed across four areas. Each area had 252 metal components, with each component measuring only 2.74x1.64mm. We needed to mark a tiny data matrix code on these micro-components, requiring the code to be black, clearly visible, and highly readable. Additionally, while ensuring high-quality marking, the solution also needed to incorporate a CCD vision positioning system. This was undoubtedly a high-difficulty challenge for us!

Project Challenges

Initially, we tested three laser types: Fiber, CO2, and UV. The Fiber laser marking was rough, not fine enough, not black, and left scorch marks. CO2 laser was unsuitable for this metal layer and could not mark it. After comparison, the UV laser yielded the best results among the three, but the initial test outcomes still didn't meet the client's demanding requirements.

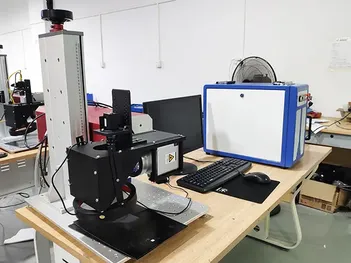

HiSpeed's technical team dedicated a week to overcoming this challenge. We tried different brands of UV laser sources, various configurations of galvo scanners and field lenses, and experimented with different focal lengths and parameters. Finally, we achieved a high-quality marking result within the stipulated time, earning the client's approval. However, our solution was only halfway complete for the entire project, as we still needed to solve the visual system's recognition and positioning issues. Nevertheless, all these challenges served as stepping stones for our team's progress. After half a month of effort, we submitted a complete solution to the client: a customized 10W UV Laser Marking Machine + CCD Automatic Positioning Vision System + XY Mobile Platform.