Czech Auto Repair Center Owner Orders 1500W Laser Cleaning Machine

Czech Auto Repair Center Owner Orders 1500W Laser Cleaning Machine U.S. Plastic Pipe Manufacturer Orders Laser Marking Machine

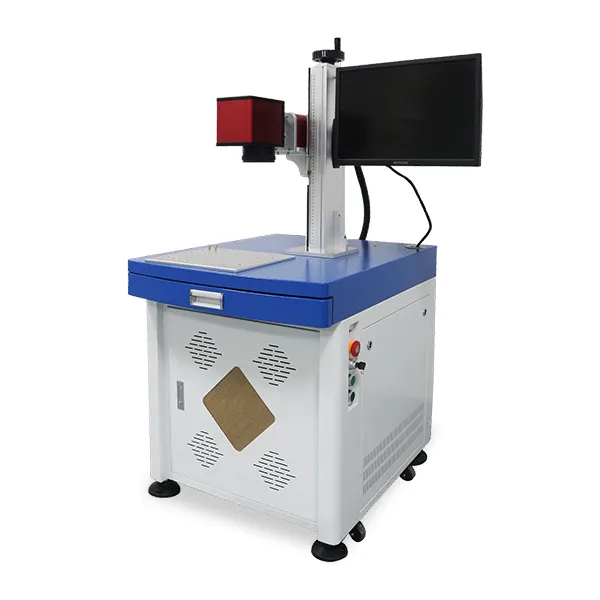

U.S. Plastic Pipe Manufacturer Orders Laser Marking Machine The UAE Jewelry Designer Purchases 50W Fiber Laser Marking Machine

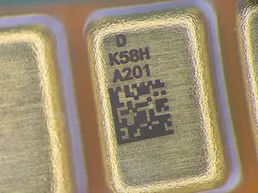

The UAE Jewelry Designer Purchases 50W Fiber Laser Marking Machine Samsung Project Manager Purchases 10W UV Laser Marking Machine

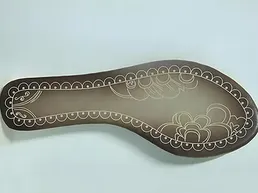

Samsung Project Manager Purchases 10W UV Laser Marking Machine  Spanish Shoe Sole Manufacturer Orders CO2 Laser Marking Machine

Spanish Shoe Sole Manufacturer Orders CO2 Laser Marking Machine Russian Animal Ear Tag Producer Orders Six-Station Laser Marking Machines

Russian Animal Ear Tag Producer Orders Six-Station Laser Marking Machines Italian Manufacturer Orders Laser Cleaning Machine

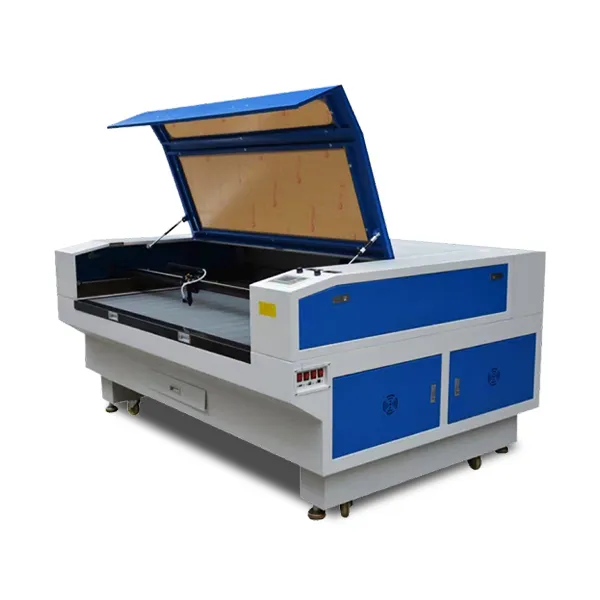

Italian Manufacturer Orders Laser Cleaning Machine Saudi Arabian Textile Artisan Orders 300W CO₂ Laser Marking Machine

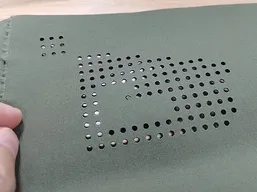

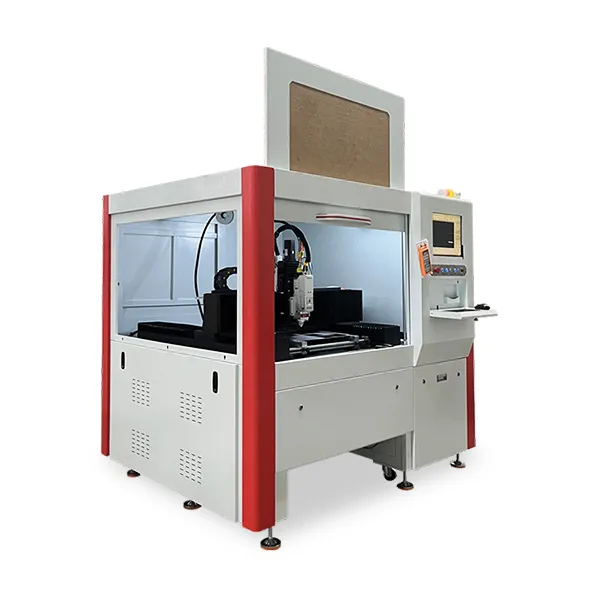

Saudi Arabian Textile Artisan Orders 300W CO₂ Laser Marking Machine

Client Background

In his crowded textile workshop, Mohamad gazed worriedly at a mountain of international orders. His manual embroidery team struggled to replicate the precise team logos of sports brands, and cutting errors with heat transfer film led to 12% material waste per roll.

Solution & Impact

The introduction of a HiSpeed 300W CO₂ laser marking machine resolved their difficulties. What once took three days for traditional plate making could now be completed in two hours with digital sample verification. Mohamad's family workshop consequently became a designated supplier for a famous brand, with orders surging by 200%. The laser not only cut fabric but also carved a path for the transformation of traditional manufacturing.