Samsung Project Manager Purchases 10W UV Laser Marking Machine

Samsung Project Manager Purchases 10W UV Laser Marking Machine  Spanish Shoe Sole Manufacturer Orders CO2 Laser Marking Machine

Spanish Shoe Sole Manufacturer Orders CO2 Laser Marking Machine Russian Animal Ear Tag Producer Orders Six-Station Laser Marking Machines

Russian Animal Ear Tag Producer Orders Six-Station Laser Marking Machines Italian Manufacturer Orders Laser Cleaning Machine

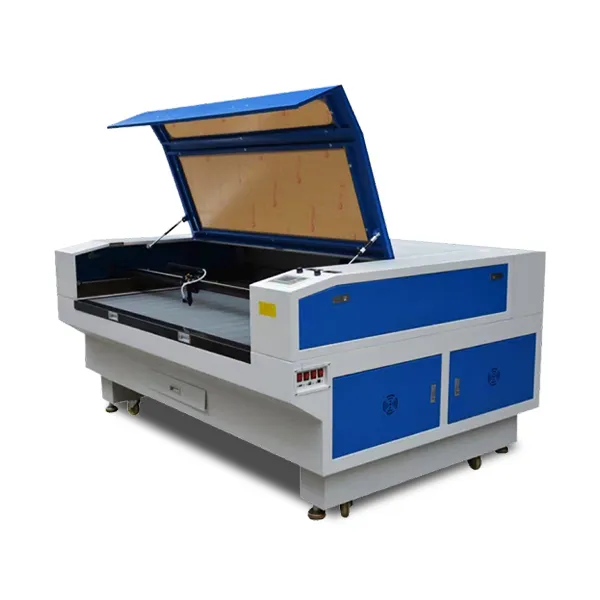

Italian Manufacturer Orders Laser Cleaning Machine Saudi Arabian Textile Artisan Orders 300W CO₂ Laser Marking Machine

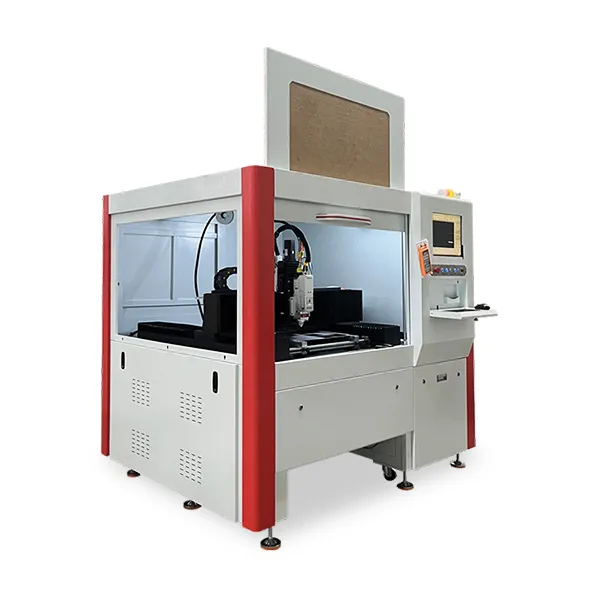

Saudi Arabian Textile Artisan Orders 300W CO₂ Laser Marking Machine Czech Auto Repair Center Owner Orders 1500W Laser Cleaning Machine

Czech Auto Repair Center Owner Orders 1500W Laser Cleaning Machine U.S. Plastic Pipe Manufacturer Orders Laser Marking Machine

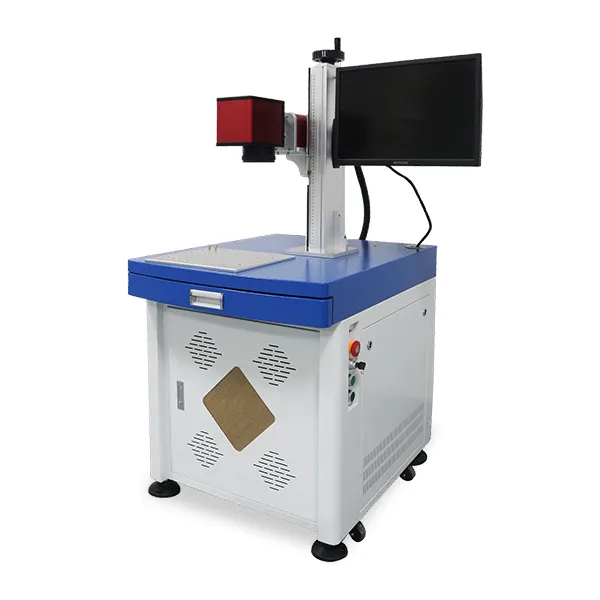

U.S. Plastic Pipe Manufacturer Orders Laser Marking Machine The UAE Jewelry Designer Purchases 50W Fiber Laser Marking Machine

The UAE Jewelry Designer Purchases 50W Fiber Laser Marking Machine

Client Background

Ella is a jewelry designer from UAE. She was looking for equipment to enhance the efficiency of her jewelry making process.

Application Scenario

Engraving and cutting thin sheets of materials like gold, silver, and copper, typically 0.5mm to 1.2mm thick.

Pre- and Post-Sales Challenges

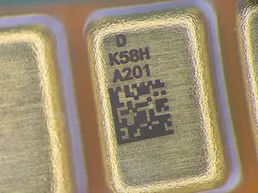

As someone new to laser equipment, Ella was very concerned about not knowing how to operate the machine, lacking after-sales service, and the machine not meeting her application needs before making the purchase. With the assistance of the HiSpeed sales team, we recommended a 50W fiber laser marking machine based on her specific application requirements. After she received the machine, we maintained close communication with Ella to ensure she could smoothly integrate the machine into her daily jewelry design work. We provided detailed guidance on basic hardware operation, artwork preparation, and software parameter settings, offering as much usage advice as possible. Through Ella's continuous learning and hands-on practice, within half a month, she was able to independently use the machine to create her first piece of jewelry. Since then, Ella has produced more and more exquisite gold and silver pendant ornaments, and this laser marking machine has successfully become one of her essential tools for daily jewelry production.

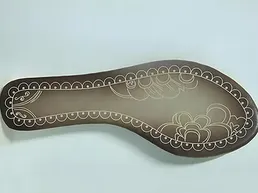

Ella often shares her creative process and results with us. One of the pictures above is a "coral" pendant she designed as a gift for her son's girlfriend, cut from a 1.2mm thick 18K gold sheet using her 50W fiber laser marking machine.