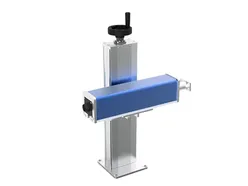

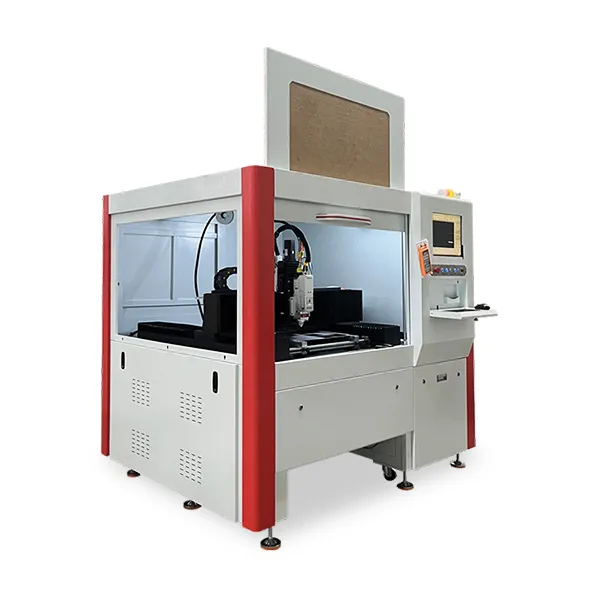

Desktop UV Laser Marking Machine

Desktop UV Laser Marking Machine

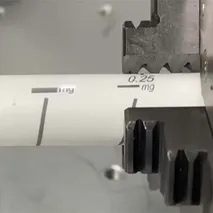

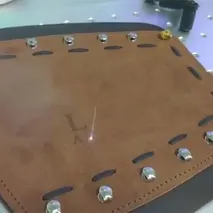

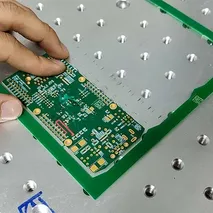

- Laser wavelength 355nm

- Marking range ≤300×300mm

- Beam quality M²<1.2~1.5

- Max. line speed 7000mm/s

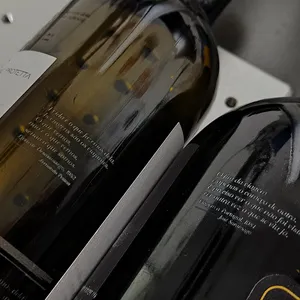

The desktop UV laser marking machine features an integrated equipment-workstation design. Its body height and operating interface angle comply with ISO 6385 ergonomic standards, adapting to a standard workbench. It reduces footprint by over 40% compared to traditional models, eliminating the need for additional production line modification, allowing a single machine to complete the entire workflow. It supports multi-mode mixed marking for text, vector graphics, 1D/2D barcodes, dynamic serial numbers, and more, with a resolution of up to 0.01mm.

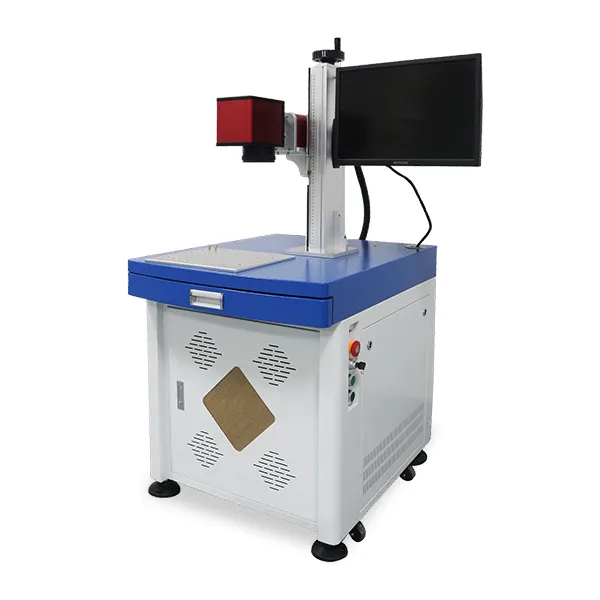

Standard Configuration

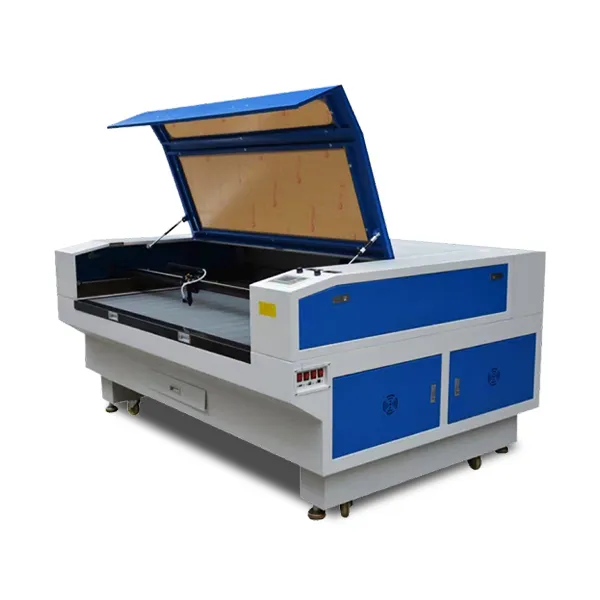

Standard Configuration Optional Configuration

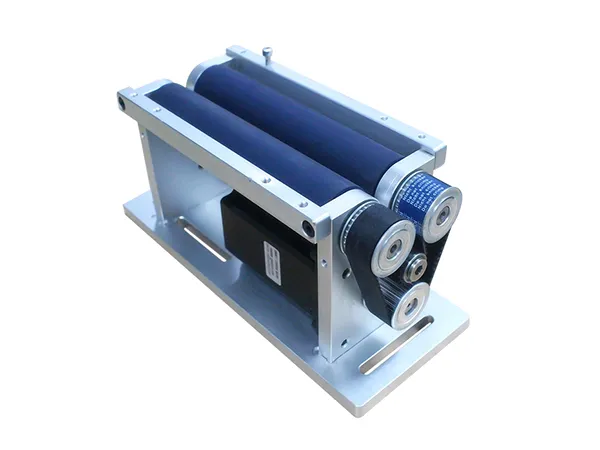

Optional Configuration Accessory List

Accessory List