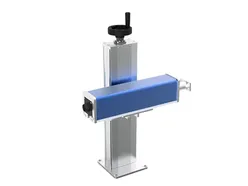

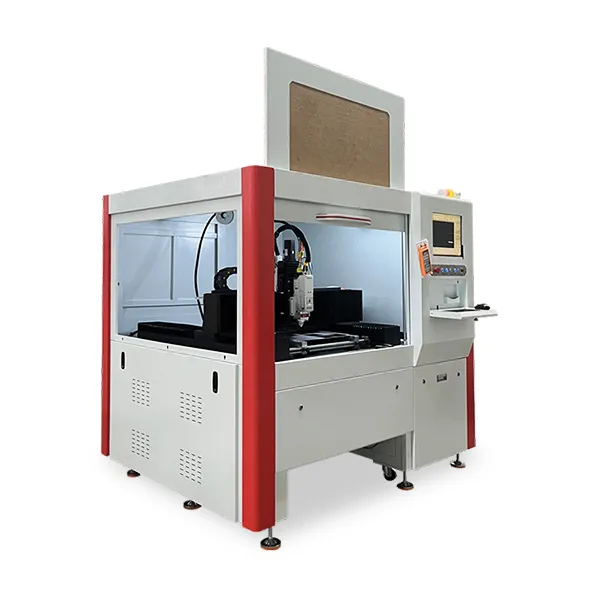

Mini UV Laser Marking Machine

Mini UV Laser Marking Machine

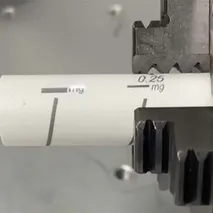

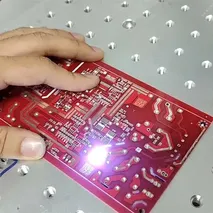

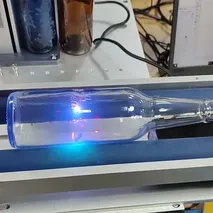

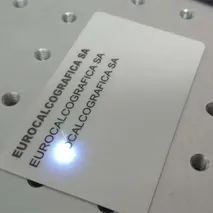

- Laser wavelength 355nm

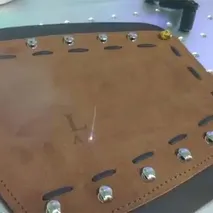

- Marking range ≤200×200mm

- Beam quality M²<1.2~1.5

- Max. line speed 7000mm/s

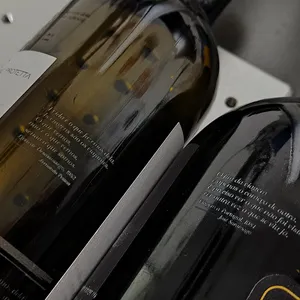

The mini UV laser marking machine redefines small-space operation standards with its ultra-compact design and industrial-grade performance. The machine body adopts an integrated structure, combining the laser source, galvo scanner, and control system into one unit. Weighing only 62kg and occupying less than 0.5m², it is perfectly suited for space-sensitive environments such as laboratories and micro-workshops. It supports 24-hour continuous operation, significantly reducing deployment costs.

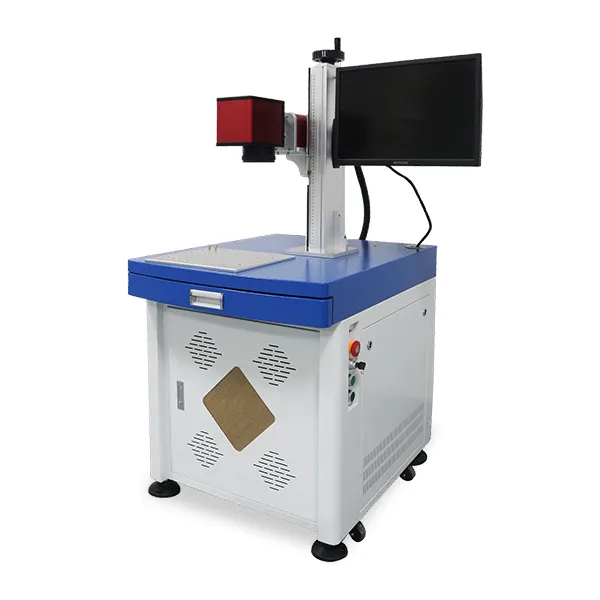

Standard Configuration

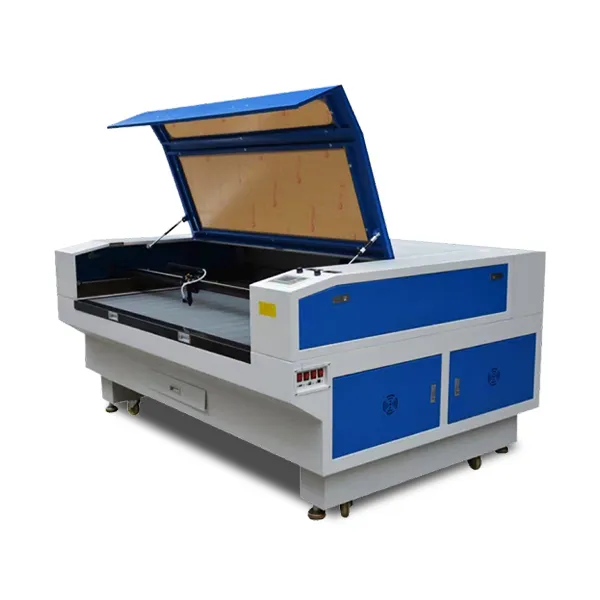

Standard Configuration Optional Configuration

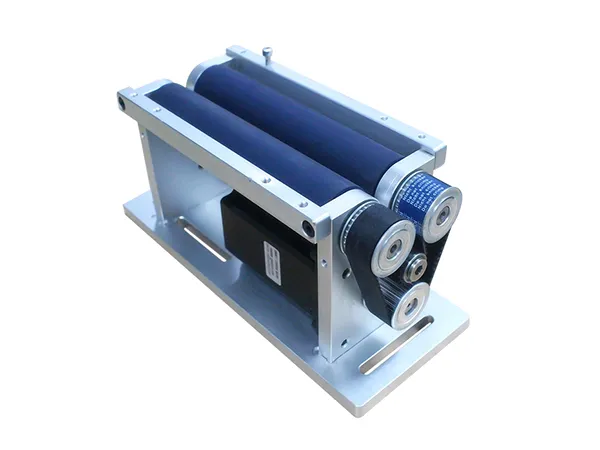

Optional Configuration Accessory List

Accessory List